Introduction

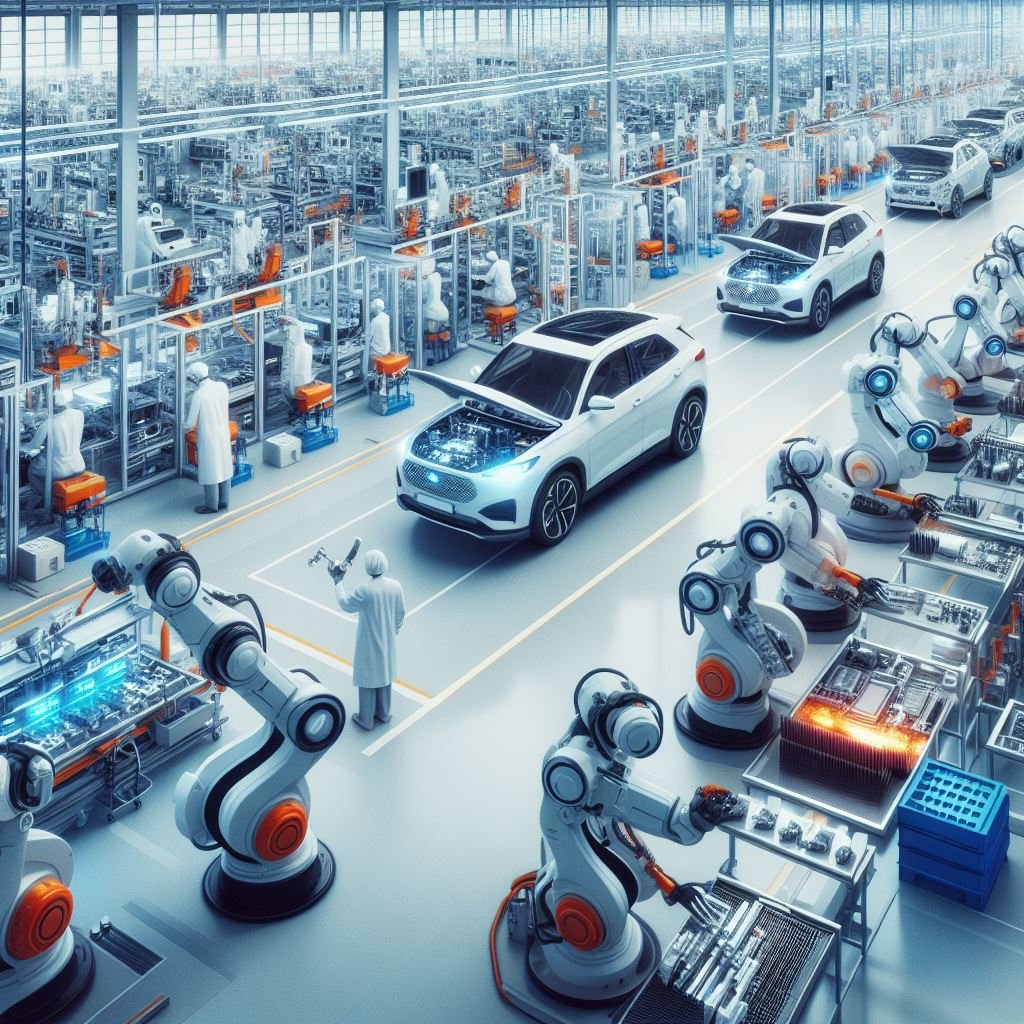

Industrial robots have become the cornerstone of modern manufacturing, transforming industries and revolutionizing the way we approach production processes. In this comprehensive exploration, we delve into the myriad applications and uses of industrial robots, showcasing their impact on efficiency, precision, and innovation.

Understanding Industrial Robots

Industrial robots, equipped with advanced artificial intelligence (AI), are automated machines designed to perform a variety of tasks in manufacturing and production settings. The integration of AI technologies has elevated these robots to new heights, making them indispensable in today’s rapidly evolving industrial landscape.

Applications in Manufacturing

Industrial robots play a pivotal role in streamlining manufacturing processes. From assembly lines to material handling, these robots enhance efficiency, reduce production costs, and improve overall output quality. The synergy between AI and industrial robots ensures adaptability to dynamic production demands.

Precision and Quality Assurance

The precision and accuracy of industrial robots make them invaluable for tasks that demand meticulous attention to detail. Whether it’s welding, painting, or intricate assembly, these robots consistently deliver high-quality results, ensuring a significant reduction in errors and defects.

Industrial Robots in Hazardous Environments

One of the standout features of industrial robot is their ability to operate in hazardous environments. From handling toxic substances to navigating challenging terrains, these robots can perform tasks that would pose a risk to human workers. AI algorithms enhance their decision-making capabilities, making them adept at adapting to unpredictable situations.

Collaborative Robotics (Cobots)

The era of collaborative robots, or cobots, has dawned with the integration of AI. Cobots work alongside human operators, enhancing productivity and safety. The seamless collaboration between humans and industrial robot showcases the potential for a harmonious working environment.

Efficiency and Cost-Effectiveness

Industrial robot contribute significantly to cost-effectiveness by minimizing production downtime, optimizing resource utilization, and reducing overall operational costs. AI-driven predictive maintenance ensures that robot operate at peak performance, preventing unexpected breakdowns.

Uses of AI in Industrial Robotics

| Use of AI in Industrial Robotics |

|---|

| 1. Automated Manufacturing Processes |

| 2. Quality Control and Inspection |

| 3. Predictive Maintenance |

| 4. Hazardous Environment Exploration |

| 5. Collaborative Robotics (Cobots) |

| 6. Material Handling and Logistics |

| 7. Precision Welding and Assembly |

| 8. Autonomous Navigation and Path Planning |

| 9. AI-Based Decision Making in Robotics |

| 10. Enhanced Human-Robot Interaction |

Conclusion

In conclusion, the integration of industrial robot with artificial intelligence has ushered in a new era of efficiency and innovation in manufacturing. The versatility and adaptability of these robots make them indispensable across various industries, from automotive to electronics. As we continue to advance technologically, the synergy between AI and industrial robot will undoubtedly shape the future of production, offering unprecedented levels of precision, safety, and cost-effectiveness. Embracing these technological advancements is key to staying competitive in the ever-evolving landscape of industrial automation.